Static vs Kinetic Friction: Understanding the Physics of Contact Forces

Static vs Kinetic Friction: Understanding the Physics of Contact Forces

Every time you push a heavy box across the floor, brake your car, or even walk down the street, you're experiencing one of the most fundamental and fascinating phenomena in physics: friction. Yet despite its ubiquity, friction is deceptively complex. It's not just a single force, but a nuanced interaction that changes dramatically depending on whether objects are stationary or moving relative to each other.

Understanding the distinction between static and kinetic friction isn't just academic curiosity—it's essential knowledge for engineers designing everything from car brakes to robotic grippers, from mountain climbing equipment to precision manufacturing systems. Let's dive deep into the physics that governs these contact forces.

The Nature of Friction: A Microscopic Perspective

Before we distinguish between static and kinetic friction, we need to understand what friction actually is at a fundamental level.

Surface Roughness and Contact

Even surfaces that appear smooth to the naked eye are microscopically rough. When two surfaces come into contact, they don't touch everywhere—only at discrete high points called asperities. At these contact points, atoms from both surfaces interact through:

- • Electromagnetic forces between electron clouds

- • Van der Waals forces and other molecular interactions

- • Mechanical interlocking of surface irregularities

- • Cold welding where asperities can temporarily bond

The Complexity of Real Friction

Classical friction models treat the phenomenon as simple and predictable, but reality is more nuanced. Real friction involves:

- • Adhesion between surfaces at the molecular level

- • Deformation of asperities (elastic and plastic)

- • Plowing where harder materials groove into softer ones

- • Third-body particles (contaminants, wear debris, lubricants)

- • Temperature effects from frictional heating

- • Time-dependent effects (surfaces can "settle" over time)

Static Friction: The Force That Keeps Things Still

Static friction is the resistance to the initiation of motion between two surfaces in contact. It's what prevents a parked car from sliding down a hill, keeps a book resting on an inclined desk, and allows us to walk without slipping.

Mathematical Model of Static Friction

The magnitude of static friction force adjusts to match the applied force, up to a maximum value:

The maximum static friction force is proportional to the normal force pressing the surfaces together:

where is the coefficient of static friction, a dimensionless quantity that depends on:

- • The materials of both surfaces

- • Surface roughness and cleanliness

- • Environmental conditions (humidity, temperature)

- • Sometimes the history of contact (surfaces can "settle")

The Self-Adjusting Nature of Static Friction

What makes static friction particularly interesting is its self-adjusting behavior. If you apply a small horizontal force to a stationary object, the static friction force exactly equals (up to the maximum):

This is fundamentally different from most forces in physics, which have fixed magnitudes. Static friction is a constraint force—it takes on whatever value is needed (within limits) to prevent motion.

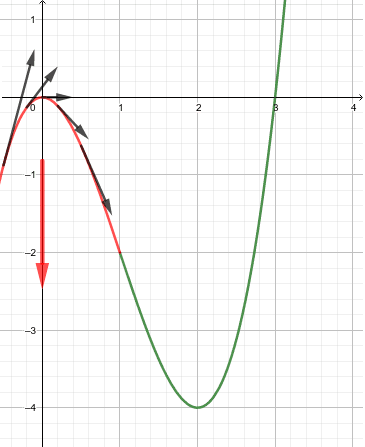

The Moment of Transition

The critical moment occurs when the applied force reaches the threshold:

At this instant, the object is on the verge of motion, in a state of impending motion. Any infinitesimal increase in force will overcome static friction and initiate sliding. This transition point is crucial in engineering design.

Kinetic Friction: The Force of Sliding

Once an object begins to move, the nature of friction changes. Kinetic friction (also called dynamic friction or sliding friction) acts on surfaces in relative motion.

Mathematical Model of Kinetic Friction

Unlike static friction, kinetic friction has a relatively constant magnitude:

where is the coefficient of kinetic friction. The kinetic friction force:

- • Acts opposite to the direction of relative motion

- • Is approximately independent of sliding velocity (for moderate speeds)

- • Is typically smaller than maximum static friction:

Why Is Kinetic Friction Less Than Static?

The fact that has important practical consequences and microscopic explanations:

Microscopic Reasoning:- • When surfaces are stationary, asperities have time to settle into stable configurations and form stronger bonds

- • During motion, asperities slide over each other rapidly, with less time to interlock or bond

- • Moving surfaces may ride slightly higher on their contact points, reducing the effective contact area

- • Dynamic effects can introduce a "lubricating" layer of wear particles

The Laws of Friction: Amontons-Coulomb Model

The classical model of friction, developed by Guillaume Amontons (1699) and Charles-Augustin de Coulomb (1785), establishes three fundamental laws:

First Law: Independence of Apparent Contact Area

The friction force is proportional to the normal force but independent of the apparent contact area. This seems counterintuitive—shouldn't a larger area create more friction?

Explanation: While larger apparent area might seem to provide more friction, it also distributes the load over more area, reducing the pressure. These effects cancel out. The real contact area (at asperities) is what matters, and it scales with normal force, not apparent area. Engineering Implication: Changing the contact area doesn't change friction (in the classical model), but changing the normal force does.Second Law: Independence of Sliding Velocity

Kinetic friction is approximately independent of sliding velocity, at least for typical speeds.

Reality Check: This is an approximation. At very low speeds (micrometers per second), friction can increase (stick-slip behavior). At very high speeds, friction may decrease due to heating effects and melting, or increase due to aerodynamic drag.Third Law: Dependence on Material Properties

The coefficient of friction is a property of the material pair and surface conditions, not the individual surfaces alone.

Typical Friction Coefficients: Real-World Values

Understanding actual friction coefficients helps develop engineering intuition:

Common Material Pairs (Dry Surfaces)

Steel on Steel- • Static: 0.74

- • Kinetic: 0.57

- • Static: 0.61

- • Kinetic: 0.47

- • Static: 0.9 - 1.0

- • Kinetic: 0.6 - 0.85

- • Static: 0.25 - 0.5

- • Kinetic: 0.2

- • Static: 0.94

- • Kinetic: 0.4

- • Static: 0.1

- • Kinetic: 0.03

- • Static: 0.04

- • Kinetic: 0.04

- • Static: 0.01

- • Kinetic: 0.003

Observations

- • High friction: Rubber on concrete (essential for tires)

- • Low friction: Ice on ice (skating), Teflon (non-stick cookware)

- • Biological sophistication: Synovial joints have remarkably low friction through sophisticated lubrication

- • Large ratio: Glass on glass shows dramatic difference between static and kinetic friction

Applications in Engineering and Physics

1. Vehicle Braking Systems

When you brake, you rely on friction to stop. The brake pads press against rotors/drums:

- • Maximum friction when pads are pressed harder (larger )

- • Heat dissipation is crucial (friction generates thermal energy)

- • Must avoid complete wheel lockup (transition from static to kinetic at tire-road interface reduces stopping ability)

- • Anti-lock braking systems (ABS) keep tires at the threshold between static and kinetic friction for maximum stopping force

where is gravitational acceleration. Notice that stopping distance is independent of mass (heavier vehicles have more inertia but also more normal force).

2. Inclined Planes and Angle of Repose

For an object on an incline at angle :

Normal force:The angle of repose is the maximum angle before sliding begins:

3. Walking and Locomotion

Walking relies on static friction between your shoe and the ground. When you push backward with your foot:

- • Your foot (ideally) doesn't slip, so static friction acts

- • This friction force pushes you forward (Newton's third law)

- • If is too low (ice, oil), your foot slips and you can't walk efficiently

For typical walking, the horizontal force required is much less than the maximum static friction, so slipping doesn't occur. But when running or accelerating quickly, you approach the limit.

4. Rope and Belt Friction: The Capstan Equation

When a rope wraps around a cylinder or post (like mooring a boat), friction can amplify the holding force enormously.

For a rope wrapped through angle (in radians) around a cylinder:

where:

- • is the tension on the loaded side

- • is the tension you need to hold

- • is the friction coefficient

- • is the total wrap angle

You can hold a load 43 times your applied force! This is why sailors can control huge loads with relatively small effort using cleats and capstans.

Beyond Classical Friction: Modern Understanding

Stick-Slip Phenomena

At very low speeds, friction can exhibit stick-slip behavior:

- Static friction holds objects stationary (stick)

- Elastic deformation builds up energy

- Sudden release causes rapid motion (slip)

- Process repeats

- • Squeaky hinges and brakes

- • Violin string vibrations (rosin provides high friction)

- • Earthquakes along fault lines

Velocity Dependence and the Stribeck Curve

The Stribeck curve shows how friction actually varies with velocity:

- Static regime (): Friction is at maximum

- Boundary lubrication (low ): Friction decreases with increasing velocity

- Mixed lubrication (moderate ): Friction reaches minimum

- Hydrodynamic lubrication (high ): Friction increases slightly with velocity

Temperature Effects

Friction generates heat:

where is power dissipated. This can cause:

- • Material property changes (softening, hardening)

- • Thermal expansion (changing fit tolerances)

- • Lubrication breakdown

- • In extreme cases, melting or burning

Practical Problem-Solving Approach

When solving friction problems in engineering:

Step 1: Identify the State

- • Is the object stationary or moving?

- • If stationary, is it on the verge of motion?

Step 2: Draw a Free Body Diagram

- • Include all forces: weight, normal force, applied forces, friction

- • Choose a coordinate system (often aligned with motion/surface)

Step 3: Apply Newton's Laws

- • Sum forces in each direction:

- • For equilibrium:

Step 4: Friction Relationships

- • Static case: (use equality only at impending motion)

- • Kinetic case:

Step 5: Solve the System

- • Often you'll need to solve simultaneous equations

- • Check that your answer makes physical sense

The Human Side of Friction

It's easy to think of friction as purely mechanical—equations and coefficients. But friction is deeply woven into human experience:

- • Touch and grip: Our ability to manipulate objects depends on friction between skin and surfaces. Neuroscientists have found that our brains have specialized mechanisms for detecting slip, allowing us to adjust grip force in milliseconds.

- • Music: String instruments rely on friction between bow and string. The rosin applied to bows increases , allowing controlled stick-slip vibrations that create sound.

- • Sports: Athletes constantly work with and against friction. Rock climbers use chalk to increase friction, speed skaters minimize it with blade design, and basketball players depend on the precise friction of their shoes on the court.

- • Evolutionary adaptations: Gecko feet use van der Waals forces for extraordinary adhesion, effectively a form of friction that allows them to climb smooth walls. Tree frogs use wet adhesion. These natural solutions inspire biomimetic engineering.

Looking Forward: Future of Friction Science

Modern tribology (the science of friction, wear, and lubrication) continues to evolve:

Nanotribology: Understanding friction at atomic scales using tools like atomic force microscopy reveals that classical laws break down at nanometer scales. Smart materials: Surfaces that can actively change their friction properties—imagine car tires that adjust friction based on conditions, or surgical tools that can switch between high-grip and low-friction modes. Computational approaches: Molecular dynamics simulations can now model friction from first principles, helping design better materials and lubricants.Mastering Friction: Engineering Intuition

Understanding friction deeply means developing intuition about:

- • When to maximize it (brakes, walking, gripping)

- • When to minimize it (bearings, slides, efficiency)

- • How to control it (lubrication, surface treatments, material selection)

- • When classical models fail and more sophisticated analysis is needed

Ready to Master Engineering Mechanics?

Friction is just one piece of the rich tapestry of engineering mechanics. From statics to dynamics, from materials science to thermodynamics, every concept builds on these fundamental principles.

With Didaxa, you can master mechanics and beyond through personalized, AI-powered learning that adapts to your pace and style. Whether you're tackling your first friction problem or designing complex mechanical systems, we guide you through every concept with clarity and depth.

Start your engineering journey today. Experience how Didaxa transforms the way you learn physics and engineering.Written by

Didaxa Team

The Didaxa Team is dedicated to transforming education through AI-powered personalized learning experiences.

Related Articles

Continue your learning journey

Why Advanced Topics Demand Advanced AI: The Ensemble Architecture Revolution

Simple chatbots fail at advanced mathematics and complex subjects. Discover why ensemble AI architecture—multiple specialized agents working together—is the only way to master calculus, physics, and advanced topics.

Differential Calculus: From Limits to Advanced Differentiation Techniques

A comprehensive exploration of differential calculus, covering limits, derivatives, and advanced differentiation techniques with rigorous mathematical foundations.

Integral Calculus: From Riemann Sums to Advanced Integration Techniques

An advanced exploration of integral calculus, covering Riemann integration, fundamental theorems, and sophisticated integration techniques with rigorous mathematical foundations.

Experience the Future of Learning

Join thousands of students already learning smarter with Didaxa's AI-powered platform.